- Solutions

- Shredder

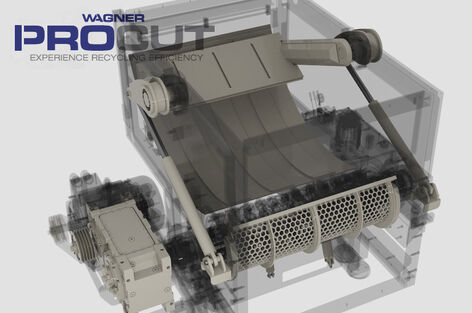

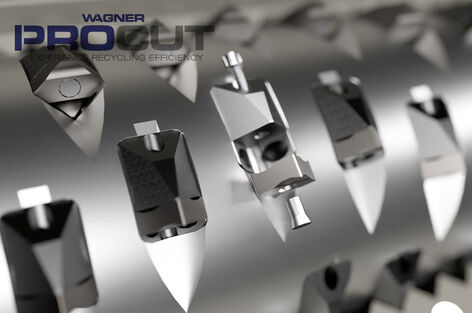

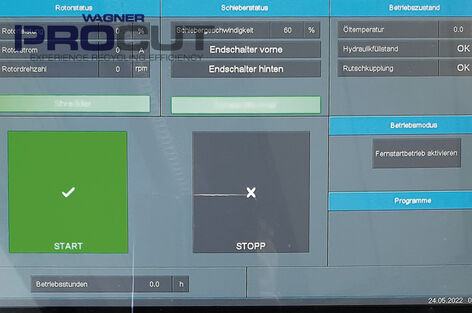

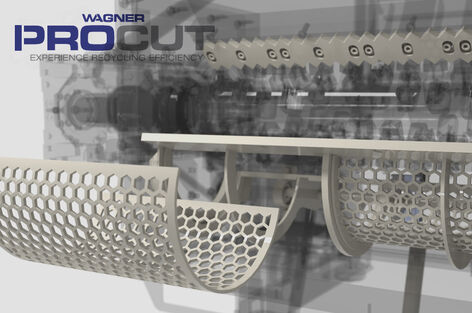

- Single Shaft Shredder ProCut 1300

- Single Shaft Shredder ProCut 1600

- Single Shaft Shredder ProCut 1900

- Single Shaft Shredder WS5

- Single Shaft Shredder WS11-15

- Single Shaft Shredder WS22

- Single Shaft Shredder WS30

- Single Shaft Shredder WS50

- Single Shaft Shredder WS70

- Twin Shaft Shredder PROSHRED 300

- Twin Shaft Shredder PROSHRED 500

- Twin Shaft Shredder PROSHRED 800

- PET Perforator

- Tyre Dismantler

- Special Solutions

- Second Hand

- Shredder

- Applications

- Best Quality

- Service

- YOUR WASTE

- About us

- Contact